The World of living national treasures

Journey into the world of

ARITA's most revered craftsmen.

The World of living national treasures

Imaemon Imaizumi

Career

Born as the second son of the Imaizumi family, who traditionally served as the official red painters for the Nabeshima clan kilns in Saga. He graduated from the Musashino Art University with a degree in Craft and Industrial Design and then studied under the ceramic artist, Osamu Suzuki.

Since 1990, he has worked under his father, the thirteenth Imaemon Imaizumi, a Living National Treasure, mastering the art of Iro-Nabeshima (colored porcelain).

He holds the distinction of being the youngest ever to be designated as a Living National Treasure (Important Intangible Cultural Property) in the field of ceramics.

Works

He has developed a technique called 'Sumi-hajiki' (ink-resist), creating unique pieces with this method. In this technique, patterns are first drawn with ink, over which cobalt blue is applied, and then fired in a kiln, resulting in the ink 'resisting' the color and revealing the white patterns.

Noticing that the core of plum blossoms drawn with traditional 'Sumi-hajiki' resembled snowflakes after firing, he began to explore snowflake patterns.

He has introduced 'Platinum Coloring', applying platinum overglaze to create a transformative white gold hue, adding a new dimension to colored porcelain expression.

Artistic Philosophy

He states that 'the work of ceramics is not about expressing fixed values, but rather about freely expressing one's thoughts at any given time.'

He also indicates his commitment to continuing the tradition of the 'Imaemon' lineage, where each generation has faced their era and forged new paths.

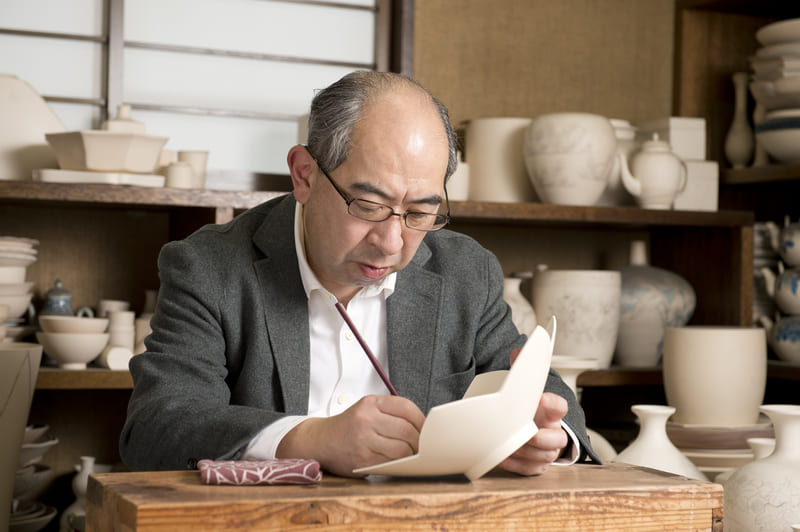

Manji Inoue

Career

Born in Arita Town, Saga Prefecture, in a family owning a kiln, he initially aspired to be a military officer. In 1944, he became a naval aviation cadet and, after the war, started working under the 13th Sakaida Kakiemon. Later, he became a disciple of Okugawa Chuemon.

He learned the techniques of white porcelain and pottery wheel, then devoted himself to developing his own designs and glazes. In 1995, he was designated a Living National Treasure for his white porcelain work.

Works

He was first selected for the 15th Japan Traditional Art Crafts Exhibition in 1968 and has since won numerous awards. In 1995, he was designated a holder of the Important Intangible Cultural Property 'White Porcelain', received the Purple Ribbon Medal in 1997, and the Order of the Rising Sun, Gold Rays with Neck Ribbon in 2003.

Focusing particularly on white porcelain, he continues to produce unique works amidst the colorful decorations typical of Arita ware. Known for the beauty of his white porcelain and simple designs, he represents the essence of traditional Japanese ceramic art.

Artistic Philosophy

He has also dedicated himself to nurturing the next generation, with over 500 students in Japan and more than 150 in the United States. Through his style, he demonstrates a commitment to preserving traditional techniques while always seeking new expressions and evolving.

Official WebsiteThe World of potter

Fukaumi Shoten

Philosophy

Fukaumi Shoten operates under the principle of 'always being grateful to customers, loving them, and being a company that is loved in return.' This philosophy is centered around deep appreciation and love for customers, reflecting a corporate attitude of building trust.

Technique

Fukaumi Shoten is known for its traditional colors and contemporary sensibilities in Gosu (cobalt blue) and glazes. The company focuses on developing unique shades and textures, exploring new possibilities in ceramics manufacturing.

Official Website

Koransha

Philosophy

Under the philosophy of refining the quality of products, beautifying shapes and painting, reducing manufacturing costs to lower the price, maintaining honor, and aiming for permanent profits, Koransha maintains the beauty and techniques of traditional Arita ware while continuously meeting the needs of the times and bravely challenging new expressions.

Technique

Koransha possesses advanced technical capabilities in the ceramics field, including the creation of art pieces that advance Arita’s traditional styles, manufacturing Japan’s first porcelain insulators, and developing fine ceramics using the latest technology. The company operates a diverse range of businesses.

Official Website

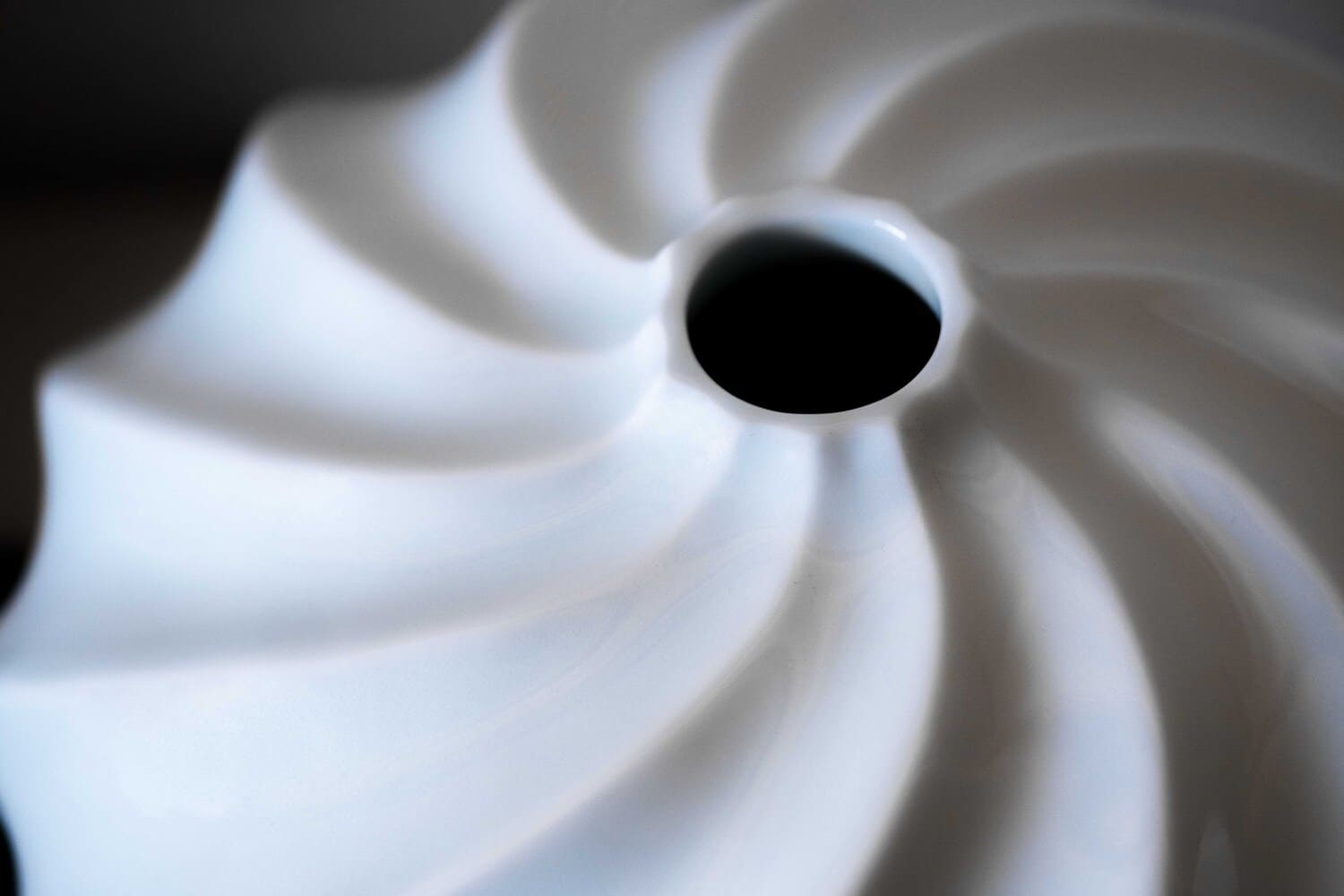

Tsuji Seijisha

Philosophy

As a kiln that crafts for the 'public,' Tsuji Seijisha pursues manufacturing that lives up to the pride and joy of being appreciated as public goods. Believing in the joy and surprise that beautiful items bring, regardless of changing times, the company continuously strives to create universally valued pieces.

Technique

Tsuji Seijisha’s distinctive technique is 'Kyokushin-yaki,' a secret method invented by the eighth-generation head, Kiheiji. This technique involves creating a vacuum inside a clay box made of the same material as the product, blocking the permeation and diffusion of gases inside, and achieving a lustrous shine and deep Gosu coloration. This unique method was successfully restored by the fourteenth-generation head, Hitachi Tsuji, in 1985.

Official Website

Riso

Philosophy

Under the belief that 'beautiful things are eternal,' Riso pursues timeless beauty in design, actively creating and producing wares. Continuing the spirit of the founder, Shinichi Terauchi, even through the era of mass production and consumption since the high economic growth period, Riso remains committed to its philosophy.

Technique

Riso specializes in 'Sometsuke' (blue-and-white porcelain) using Gosu. The hand-painted decorations by skilled artisans inherit traditional patterns like Old Imari. Additionally, series such as 'Shinogi' combine traditional Shinogi techniques with the latest digital technology, producing functional and advanced wares that blend Arita's tradition and innovation.

Official Website

Koda Clay

Philosophy

Supporting an essential role in the production of Arita and Imari wares, Koda Clay has been producing high-quality clay for over 133 years. Its use by Living National Treasure Manji Inoue attests to its quality and reliability.

Technique

In the manufacturing process of Koda Clay, the ‘polishing operation’ to remove red iron oxides from the finest pottery stone is crucial, requiring the skill of experienced craftsmen. The process of turning pottery stone into powder using a 'stamper' and dissolving it in water relies heavily on the craftsman's experience and intuition. Finally, they produce 18% moisture content clay slabs, used to create Arita and Imari wares.

Official Website